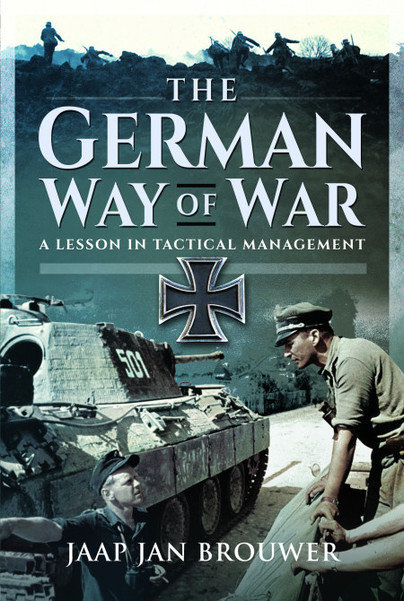

Author Guest Post: Jaap Jan Brouwer

THEN AND NOW:REPAIR AND MAINTENANCE OF TANKS AND OTHER EQUIPMENT

The last two weeks the Ukraine army has been very busy along the frontline, looking for the Schwerpunkt.. That leads to damaged tanks and other equipment, a situation similar to that of the Wehrmacht in de Second World War. Here the way the Germans did the job. Learn more about the German way of war (and in extension the Ukraine way of war) in my book ‘The German way of war. A lesson in tactical management’ and in ‘The German way of war on the Eastern Front 1941 – 1943’(release date October).

On the Eastern Front

The campaigns of the German Army had up till Barbarossa been characterized by their short duration. This meant that tank repairs and maintenance had generally taken place after the successful completion of a campaign. Damaged tanks were collected and transported to workshops located in Germany. The invasion of the Soviet Union, however, placed completely different demands on this system. Firstly, the number of damaged tanks was almost 50 per cent higher than in previous campaigns; the number of tanks requiring repair or maintenance for other reasons was also much higher. This, and the great distances involved, meant that the previously successful system of centralized repair and maintenance was no longer adequate, and it was replaced by decentralized field workshops. It took some time to build this alternative system. People and equipment had to be moved to places close to the front line. In addition, a logistics and stock system of spare parts had to be built, not only for tanks but for all vehicles. This was a Herculean task. The composition of the vehicle fleet was unprecedentedly diverse: makes and models from all over Europe were represented, which made an efficient spare parts and maintenance system virtually impossible (comparable with the present situation). Gruppe Mitte carried a total of more than a million spare parts, and a Panzer Division reported in mid-1941 that it had 96 different types of vehicles for the transport of men, 111 different types of trucks and 37 different armored vehicles. The Germans had to redesign their entire tank maintenance system.

The wear and tear from the terrain and the weather was enormous. The same Panzer Division reported in November 1941 that only 12 per cent of its fleet was operational. Furthermore, an evaluation by the 18th Panzer Division, for example, demonstrated the consequences of insufficient spare parts: 59 tanks could not be deployed due to enemy actions, but 103 tanks were standing idle due to lack of spares. But the problem was much bigger than this: German industry simply produced too few spare parts. It had focussed too much on production and failed to realize the large quantities of spares which would be needed to keep tanks or trucks rolling once they were delivered. The situation slowly improved in 1942 and 1943, but because of the long supply lines and the diversity of vehicles, some had to be sidelined for weeks and occasionally months. Another important task was the salvaging of damaged tanks from the battlefield. In the previous campaigns, damaged tanks could be easily towed to assembly points for further transport after battles. In the Soviet Union this was not always possible, and the Germans developed a system whereby tanks were repaired on the spot during combat or were towed away to undergo emergency repairs just behind the front.

Tank salvage in battle: roadside assistance on the battlefield

During the Polish campaign and the campaign in the west, towing and repairing stranded armour was relatively easy. After the battle was over, the armour was simply collected and transported by rail to workshops in Germany. In North Africa and the Soviet Union the situation was completely different. It was necessary to constantly maintain combat power, and being able to tow tanks away from the battlefield became a criterion of success and developed into a specialism. The Germans established special Abschlep Abteilungen (towing units) for this, using their Sd.Kfz. 9 FAMOs and other vehicles. The SdKfz FAMOs were at 18 tons the heaviest members of the Sd.Kfz. family and were developed for towing 21cm and 24cm howitzers. A single SdKfz FAMO could tow a Pz.Kpfw. III or IV tank, but heavier tanks like the Panther and Tiger of later years required three FAMOs. They were connected with 5m steel cables and then towed away under the supervision of the commander of the recovery unit in the front vehicle. These units operated in close collaboration with the tanks they supported. Damaged tanks were often repaired or towed away under enemy fire. These units were also active at night, recovering their own or useful enemy equipment left on the battlefield. The deployment and the quality of these units and the workshops further behind the lines enabled the Germans to compensate somewhat for the superiority of their opponents’ equipment by having a large proportion of the damaged tanks ready for combat again in a short time.)

If this was not possible, the damaged tanks were transported on low-loaders to field workshops further behind the front. This meant that the number of operational tanks varied from day to day and hour to hour. The field workshops also generally stocked large quantities of spare parts, including complete engines, and had equipment such as machine benches, hoist installations, welding equipment and the like. Tanks which were badly damaged or had to be completely overhauled were transported to central workshops of the Heeres Instandsetzungsgruppen (special maintenance groups), located far behind the front.

In this way the Germans were able to deploy the maximum number of panzers. When looking at the situation in the Ukraine we see damaged Western tanks, but these can be repaired after being recovered from the battlefield; Russian tanks are likely to explode and can in most cases not be repaired.

Order The German Way of War here.